Advancing innovation from laboratory to

launch

We focus on advancing small molecules and

next-gen modalities like ADCs, oligonucleotides, and peptides, ensuring efficient,

sustainable, and scientifically rigorous transitions from development to GMP-compliant

manufacturing.

Chemical Development Overview

The Chemical Development department provides

end-to-end process development and bulk manufacturing in both cGMP and nGMP modes. Our

advanced PRD lab, with integrated safety and engineering capabilities, ensures smooth

scale-up and production.

Operations across our sites in Bengaluru and

Mangaluru support business continuity,

addressing supply chain, compliance, documentation, and workforce resilience.

We are advancing next-gen modalities like

ADCs, oligonucleotides, and peptides, working

closely with customers to develop payloads, linkers, and conjugation strategies for

mAbs.

To drive sustainable innovation, we’re

investing in biocatalysis for cleaner, more

efficient synthesis and expanding expertise in Photoredox and flow chemistry.

Performance Overview

Development services performed steadily in

FY25, fueled by repeat orders and new integrated collaborations from drug development to

clinical-stage manufacturing. Early-stage small molecule process development saw strong

growth, with successful project deliveries paving the way for future expansion.

We focused on enhancing capabilities,

upgrading facilities, and onboarding experts for emerging pharmaceutical modalities.

Streamlined documentation processes ensured timely deliveries while maintaining

regulatory compliance.

Capability Expansion

- We established a dedicated laboratory for

potent molecule synthesis, boosting our ability to manage complex projects. Our

upgraded Chemical Development Laboratory is now operational, increasing project

throughput, with a specialized hazardous lab for safe handling of cyanide and toxic

reactions.

- A bench-top biocatalysis capability for

new modalities was developed, with enzymatic screening underway. Additionally, a

state-of-the-art facility at our Mangaluru site was commissioned to handle OEB-4

(Occupational Exposure Banding) molecules, enhancing our capacity for high-potency

compounds.

Pioneering Breakthroughs in Process

Innovation

Our team collaborated with global customers,

adopting advanced methodologies to improve yield, purity, and cost efficiency without

compromising safety or quality. Achievements included reduced manufacturing costs,

minimized waste, and optimized results beyond initial expectations.

The peptide and oligonucleotides teams drove

significant process improvements, ensuring timely, high-quality solutions. Additionally,

the CD-PRD team published a paper in Organic and Process Research & Development (2024)

on successfully scaling a stereoselective cyclopropanation for Factor-D inhibitors,

overcoming challenges with pyrophoric reagents under cryogenic conditions. The

publication recognized 12 Syngene co-authors.

Advancing Sustainable Practices

- We optimized the process for a rare

disease molecule, reducing PMI from over 40 to below 15, increasing yield to 60%,

and halving cycle time. This improved process delivered 26% more product with the

same raw materials, reducing waste and improving resource efficiency.

- A scalable process for an alcohol-based

intermediate enhanced reaction efficiency and reliability, increasing yield by 10%

and reducing Cost of Goods Sold (COGS) by 5%. We also optimized an ADC molecule

process, addressing crystallization and purification challenges, resulting in a 10%

reduction in E-factor and minimizing waste.

- To drive sustainable innovation, we are

investing in biocatalysis for cleaner, more efficient synthesis and expanding

expertise in Photo redox, electrochemistry, and flow chemistry.

Innovative Synthetic Approaches

Integrated Drug Development (IDD)

Program

- In collaboration with a U.S. based

biotech firm, we developed a polymer-based drug for a rare inherited metabolic

disorder. The process was successfully scaled up for bulk batches, optimizing raw

material use and cycle times, and is now ready for cGMP manufacturing.

- The team also developed a novel

activated polymer for enzyme conjugation, with plans for cGMP scale-up. The process

aligns with sustainable practices, reflecting our commitment to green chemistry.

Additionally, we developed a polymer library for RNA encapsulation in genetic

disorder treatments, completing the project on time and maintaining high material

quality.

Enhancing Quality Excellence and Productivity

The PRD team identified documentation and

plant support as productivity barriers. To

address this, a dedicated team was formed to simplify SOPs, reducing turnaround time and

eliminating non-value-added tasks. This streamlined approach improved focus on core

activities, ensured seamless customer communication, and led to smoother operations and

successful project outcomes.

Innovations in Material Science

We partnered with a customer to develop ionic

materials for clean energy, achieving four times the stability and performance of market

benchmarks. Large-scale production of 300-meter membrane rolls was successfully

executed, advancing decarbonization efforts.

The team also developed a novel library of

cross-linkable polymers for Printed Circuit Board (PCB) applications, with ongoing

investigations into crosslinking reactions. Additionally, a polymer was successfully

conjugated with a therapeutic protein, advancing its potential for rare

disease treatment.

Risk Management

We successfully managed the handling of TMSCN

(cyanide) in an acidic medium, effectively controlling the release of hazardous HCN

(hydrogen cyanide) gas. A thorough risk assessment was conducted from raw material

procurement to manufacturing, with all safety recommendations implemented. The safe

execution of three batches was shared with the customer, who praised Syngene’s risk

management protocols.

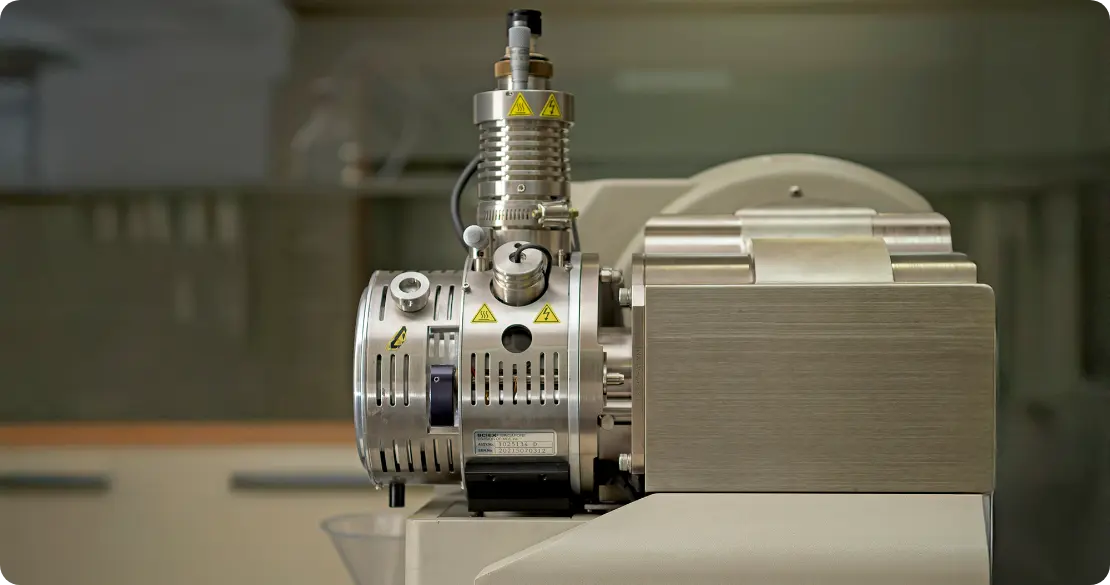

Analytical Development

The team completed its first chiral

purification by Supercritical fluid chromatography (SFC) for linker moiety at the

manufacturing facility, boosting QC confidence for future projects. New customers were

onboarded, and high-value analytical method development proposals were received,

showcasing our technical expertise.

A new model introduced staged training for

process chemists on UPLC/HPLC for IPC analysis. Capabilities were enhanced with Prep

HPLC, Arc HPLC with SEC-MALS (Size Exclusion Chromatography with Multi-Angle Light

Scattering), and potent molecule prep isolation. Over 90% of projects are now recorded

in electronic lab notebooks, improving efficiency and data security. A phase gate

quality system was also implemented to ensure Right First Time accuracy during method

transfers.

Syngene Joins ACS Green Chemistry

Roundtable

Syngene has joined the American

Chemical Society Green Chemistry Institute Pharmaceutical Roundtable (ACSGCIPR)

as an associate member, strengthening our commitment to sustainable innovation

in pharmaceutical development.

This membership enables collaboration

with global leaders like Pfizer, AstraZeneca, and Amgen, expanding our expertise

in flow chemistry, solvent selection, biocatalysis, and emerging technologies.

It offers opportunities for scientific exchange, publications, and collaborative

research, reinforcing Syngene’s position as a sustainability-driven CDMO

partner. Our inclusion reflects both our scientific strength and alignment with

global green chemistry goals.